From Box to Better

Collect

Customers, including individuals and recycling partner brands from all over Australia, send us their textiles regardless of their state. We pride ourselves on making this process seamless and simple.

Our approach for recycling partnerships is always carefully considered to deliver a balance of financial and social benefits. For our journey towards fashion circularity to be realised, we need to make it easy and appealing for both organisations and individuals.

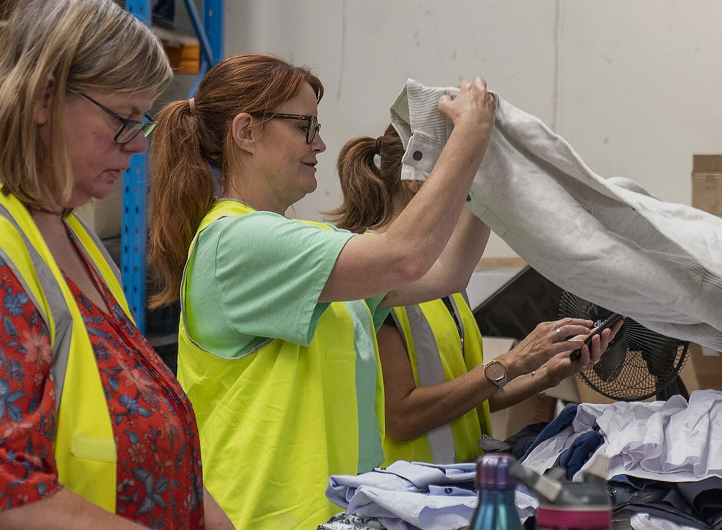

Sort

Once textiles arrive at our warehouse every item is identified and sorted through to ensure whether it’s fit for wear or unfit for wear. Each item is graded by our sorting team and analysed to be sorted into two overarching categories: reuse and recycle.

For the items that can be reused, we then separate that product into subcategories, like men’s tops, women’s pants, kids’ shoes, etc.

Textiles like damaged, worn out, and stained clothing, or uniforms with official logos can’t be reused and are sorted into different categories depending on their suitable recycling channel.

Re-use

For items that are still fit for wear, we have an open-door policy for charities, social enterprises, and not-for-profits. They can come to our warehouse and collect as much clothing as they need, go out and make an impact with it, and return anything that is unused free-of-charge.

Every charity and social enterprise we vet to ensure they are Australian-based and that the textiles provided will remain on-shore. We are providing them with guaranteed wearable goods and reducing the burden for these not-for-profit organisations to dispose of textile waste.

Recycle

Where items are not fit for wear, we break down the textiles into a variety of categories depending on their material and decommissioning required. From there, we begin the recycling process.

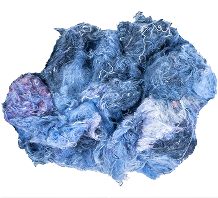

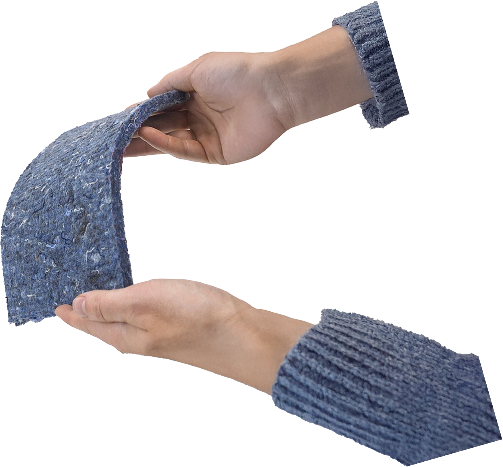

Mainly, this means taking these textiles and tearing them into a super fine fluffy fibre. This material we call FillUP can be utilised as is to replace virgin polyester fill for cushions and stuffed toys.

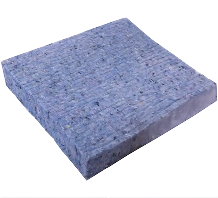

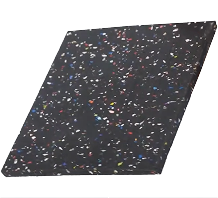

To take it one step further, we’re able to compress this fibre to create our revolutionary circular product, UPtex. This completely recycled and recyclable material can be used for packaging, signage, homewares, and more!

In addition to our UPtex recycling process, our comprehensive sorting operation allows us to support other industry leaders with suitable feedstock for their recycling approach. Why compete when we can collaborate!

Repurposing for a Circular Fashion Future

The textiles for recycling have just as much use as those that can be still worn. The textile waste recycling process sees us do several things, the most common being to tear them into a loose, fluffy fibre that’s then compressed into a rigid panel called UPtex. With an endless amount of possible applications, this revolutionary material is set to shake up the industry for the better.

Soft UPtex Panel

UPtex Prototype

FillUP Fibre

Rigid UPtex Panel

Together we divert textiles, lower carbon impact, and showcase your organisation’s environmental responsibility.

Items Saved

We’re seeing the majority of the items that we collect fit to be reused by those who need it most and support circular fashion.

Gases Prevented

For every single kilogram you send to us you will prevent 3 – 4 kg of greenhouse gases from polluting our atmosphere. That ought to help you breathe a little easier (literally!).

Diverted from landfill

Made up of clothing, linen and shoes - this is how many items we’ve been able to save from landfill. Keep an eye on this space, we update this regularly to celebrate our epic impact!

Items Reused

We’re seeing the majority of the items that we collect fit to be reused by those who need it most and support circular fashion.

Partners

Together with visionary partners we create opportunities to reduce and reuse waste with clothing donation bins, online solutions and more.

Upcycling Pioneers

Thank you to those who’ve joined us in our journey so far towards textile landfill eradication. Let’s make a difference together.

Let's Work  Together

Together

Partner with Upparel to transform textile waste into measurable impact.